Recently, a research team from the Korea Advanced Institute of Science and Technology (KAIST), together with Korea University, the Korea Institute for Basic Science, and Chung-Ang University, announced the development of a novel photoactivated chemielectric gas sensing technology. This technology combines conductive metal-organic framework (cMOF) materials with Micro LEDs, successfully achieving high-sensitivity, low-power gas detection at room temperature.

The research team stated that this latest achievement lays the foundation for a new generation of intelligent "electronic nose" (e-nose) sensing systems. The relevant research results have been published in the academic journal *Nature*.

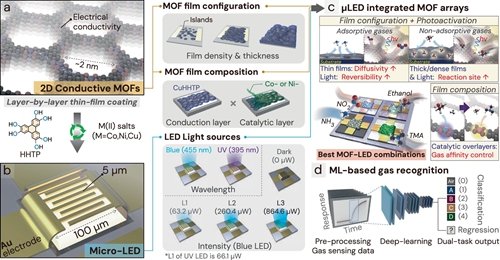

The structure of an ultra-low-power Micro LED gas sensor with an integrated two-dimensional conductive metal-organic framework (cMOF) layer allows the device to be used as both a gas sensor and an electronic nose (e-nose). (Image source: Nature)

Researchers point out that conductive metal-organic frameworks (cMOFs) are considered ideal chemielectric materials due to their diverse structures, abundant porosity, tunable chemical properties, and room-temperature conductivity. However, traditional cMOF gas sensors still have limitations in terms of sensitivity and reversibility.

To address these challenges, the research team employed a layer-by-layer deposition technique to uniformly deposit cMOF thin films onto Micro LED substrates, thereby precisely controlling the film thickness and structure. This method not only improves gas adsorption and reaction efficiency but also enables the sensor to achieve rapid and reversible responses under illumination.

The study utilized M₃HHTP₂ type cMOFs composed of three different metals (copper, nickel, and cobalt). Cu₃HHTP₂ was used as the primary sensing layer due to its stable conductivity, while Ni₃HHTP₂ and Co₃HHTP₂ were stacked on top as catalytic layers to enhance the reactivity with specific gases such as ethanol, trimethylamine, ammonia, and nitrogen dioxide. This multilayer structure was meticulously optimized, enabling the sensor to exhibit tunable sensitivity and selectivity in various gas environments.

Meanwhile, the research team conducted photoactivation tests using Micro LED light sources of different wavelengths and intensities. Blue light (455 nm) and ultraviolet light (395 nm) were proven to effectively excite the charge transfer process inside the cMOF, generating electron-hole pairs, thereby improving the gas reaction rate and detection sensitivity. The entire sensing system consumes only 587 microwatts, far lower than the energy consumption of traditional gas sensors.

cMOF gas sensor integrated on a Micro LED platform (Image source: Nature)

Furthermore, it is worth noting that the researchers also combined deep learning algorithms, utilizing convolutional neural networks (CNNs) to perform pattern recognition and classification analysis on the real-time response signals of the sensor array. The system can identify different gases within tens of seconds, with a concentration prediction accuracy of up to 99.8%. This method of combining artificial intelligence with light-activated cMOF-μLED arrays significantly improves the accuracy and response speed of the sensing system.

The research team stated that this study demonstrates the feasibility of integrating cMOF with Micro LED, providing a new path for realizing high-performance, low-power, multi-gas identification smart sensors, and opening up new development directions for gas sensing technology in the fields of environmental monitoring, industrial safety, and medical testing.