MIP technology has become a major highlight at major LED display exhibitions this year. Whether it's the Shenzhen International Smart Display and System Integration Exhibition (ISLE 2025), or international exhibitions such as the European Audiovisual Technology and System Integration Exhibition and InfoComm 2025 in the United States, MIP has become one of the key technical solutions showcased by LED display companies.

According to incomplete statistics, since the beginning of this year, many LED companies, including ChipInfo Optoelectronics, Unilumin Technology, Leyard, Lehman Optoelectronics, Nationstar Optoelectronics, Zhongqi Optoelectronics, Jingtai Optoelectronics, Richtek Semiconductor, Visionox, and Amex, have launched their latest MIP technology products, forming more diversified packaging development paths to meet different market demands.

On the production side, the development of MIP is also quite active. Companies such as Nationstar Optoelectronics, Leyard, Sanan Optoelectronics, BOE Huacan, etc. have expanded their MIP production capacity, which has enabled MIP costs to gradually decrease and its application scope to gradually expand.

"2025 is the inaugural year for the development of MIP," Xie Shaojia, R&D Director of the RGB Device Business Unit at Nationstar Optoelectronics, summarized at a recent self-emissive display symposium, reviewing the latest advancements in MIP technology. Therefore, 2025 may lay a crucial foundation for the large-scale commercialization of MIP technology in the future.

Xie Shaojia, R&D Director of the RGB Device Business Unit of Guoxing Optoelectronics

MIP technology development in 2025 exceeded industry expectations . As an extension of SMD technology, MIP (Mini/Micro LED in Package) is a display solution that encapsulates Mini/Micro LED chips at the chip level through mass transfer technology, ultimately achieving self-emissive display.

MIP combines the advantages of mature packaging technology with the innovative features of Mini/Micro LED and mass transfer technology, making it suitable for the current development trend of fine-pitch applications in the LED display industry.

Therefore, although a latecomer to LED packaging technology, the industry is quite optimistic about the development prospects of MIP. With the passage of time, MIP technology is now on a fast track of development.

Xie Shaojia believes that, from multiple perspectives, MIP's current development has exceeded industry expectations and is shedding its "high-priced, niche" label. This is the result of multiple positive factors.

First, from the perspective of the industrial chain, the entire LED industry chain is supporting the development of MIP technology capacity. Whether it is upstream chip manufacturers, midstream packaging manufacturers, or downstream panel manufacturers, all companies are investing in and deploying MIP technology, forming a strong industrial synergy for MIP technology.

In terms of technological research and development, MIP's R&D investment has also reached new heights, driving the rapid iteration of MIP technology. According to relevant statistics, more than 800 new patent applications for MIP were filed in 2025, and investment in related equipment is also increasing.

With the support of the entire industry chain and active investment in corresponding technologies and production capacity, MIP applications continue to advance towards the micro-pitch field of P0.9 and even smaller P0.7 and below. Moreover, MIP has gained a considerable competitive advantage in terms of both yield and overall cost. While breaking down pixel barriers, MIP has also lowered the threshold for the industrialization of micro-pitch technology, allowing more LED companies to enter the micro-pitch market and explore new opportunities in the LED display industry.

Nationstar Optoelectronics Becomes a Key Driver of MIP's Rapid Development <br /> In this wave of rapid growth in MIP technology, Nationstar Optoelectronics is undoubtedly one of the key drivers. Leveraging years of experience in the LED packaging industry, Nationstar Optoelectronics has established a clear MIP technology development strategy through earlier planning, greater resource investment, higher standards, richer technology reserves, and stronger upstream and downstream collaboration capabilities, continuously promoting the upgrading, optimization, and application of MIP technology.

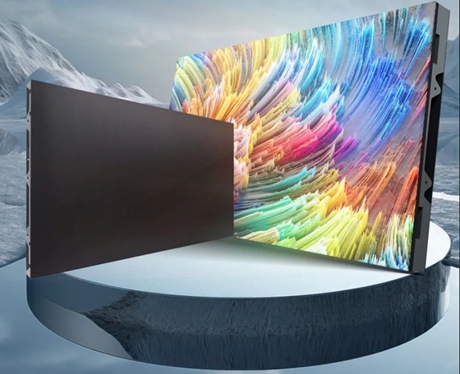

On the product side, Nationstar Optoelectronics has successively launched a series of MIP device products such as MIP0202, MIP0404, MIP0606 and MIP1010, which fully support common cathode and common anode solutions, continue the mature SMD process, and have extremely high light output consistency, high contrast and high image quality, which can meet the personalized design of different pixel pitches from P0.6 to P1.5.

MIP device series (Image source: Nationstar Optoelectronics)

To advance MIP technology from devices to panel forms with lower system costs, Nationstar Optoelectronics launched its latest AS panel series in April this year. Through the integration of MIP, module, and GOB technologies, the product structure is optimized, the process flow is reduced, the cost is lowered, and the customization flexibility is improved. It also provides OEM and ODM service solutions, covering P0.7~P1.5 pitch applications, to accelerate the popularization and application of MIP technology with better display effects and superior product performance.

AS panel series (Image source: Nationstar Optoelectronics)

In terms of production capacity layout, Guoxing Optoelectronics' MIP capacity plan demonstrates its determination to continuously advance MIP technology. In March of this year, Guoxing Optoelectronics revealed that the company had achieved a production capacity of 2000KK/month for MIP products. With the expansion and completion of Guoxing Optoelectronics' Geely Industrial Park, it will fully meet the demand for new displays and Micro LED displays, providing a solid foundation for the large-scale deployment of MIP products.

MIP's Three Core Advantages Reshape the LED Display Industry Ecosystem <br /> Although MIP technology is still in the early stages of mass production and its cost advantage is not obvious in the short term, Nationstar Optoelectronics values the long-term development value of MIP technology and its profound impact on the LED display industry.

Hsieh Shao-chia stated that Nationstar Optoelectronics is optimistic about the future development value of MIP packaging technology, not only because it is a new type of packaging device, but also because MIP is profoundly reshaping the entire LED display industry ecosystem in a completely new way.

Firstly, MIP brings industrialization advantages to Mini/Micro LED display technology. Xie Shaojia explained in detail that the core advantage of MIP lies in solving the key process problems of Micro LED chip packaging. By adopting the combination of MIP and mass transfer, it has achieved the advantage of large-scale mass production, further promoting the application of Micro LED technology.

Secondly, there is the cost advantage brought by MIP. With the investment of major manufacturers, the cost of MIP is rapidly decreasing, and the ramp-up speed of production capacity is exceeding expectations. Xie Shaojia pointed out that the massive manufacturing experience brought about by the mass production stage of MIP technology in the future will feed back into the continuous optimization of MIP processes. This will greatly shorten the subsequent MIP R&D cycle, forming a virtuous cycle and driving MIP costs to further decline.

Finally, there is the advantage of MIP's modularity, which breaks through ecosystem bottlenecks and realizes "packaging as a module." Xie Shaojia believes that modularity is the most revolutionary feature of MIP technology. In the traditional industry chain, the roles of packaging plants and module/panel plants are clearly distinct, but the emergence of MIP has broken the original product ecosystem.

Specifically, the modularity of MIP (Micro-Instrument Packaging) further enhances the protection of LED display products and improves yield rates. Furthermore, its modularity allows the production process of LED display modules to be moved forward to the packaging stage, simplifying the LED display production process, breaking it down into smaller parts, and lowering the barrier for downstream customers to enter the micro-pitch display field.

Thanks to the three major advantages mentioned above, MIP display solutions are now achieving breakthroughs across all scenarios. LED display solutions based on MIP technology are moving from traditional professional-grade large screens to home theaters, retail display cases, museums, and even in-vehicle central control, wearable devices, and AR/VR glasses applications.

In the future AI era, MIP (Multi-In-One) displays will become a powerful tool for enabling the rapid development of AI technology. Xie Shaojia believes that MIP display solutions will be the perfect carrier for realizing the vision of "display + AI + scenario services". The high reliability, design flexibility, and all-scenario application capabilities of MIP will give LED displays more value and provide more precise scenario-based solutions for AI technology content.

Summary <br /> As one of the carriers of MLED technology, MIP technology is rapidly maturing. In the future, with the continued efforts and comprehensive deployment of leading companies across the entire industry chain, such as Nationstar Optoelectronics, in technology, products, and production capacity, MIP technology will accelerate the breakthrough of final cost and industrialization barriers, becoming a key force driving the LED display industry into the era of micro-pitch development. (Text: Irving)