Recently, BOE's research team published a paper titled "Novel Package Design Enhances Optical Efficiency of Micro LED Displays" in the journal Information Display.

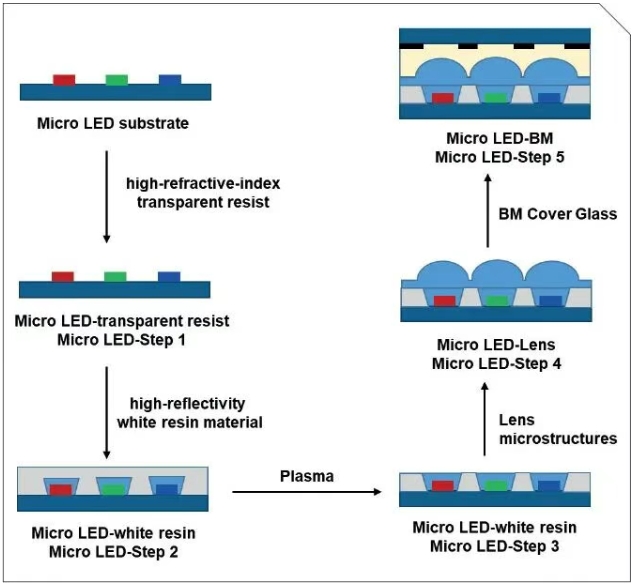

MicroLED display microstructure packaging design process (Image source: Information Display)

This study proposes an innovative Micro LED packaging solution that successfully solves industry technical challenges such as strong sidewall luminescence, low light energy utilization, and color deviation in micro LED chips.

It is understood that as pixel size shrinks to below 50 micrometers, the chip sidewall area increases relatively, resulting in enhanced lateral light emission and weakened top light emission of Micro LED, which causes brightness loss and color deviation, thus restricting the application of Micro LED in high-precision display scenarios.

To address this issue, BOE's research team developed a composite encapsulation structure consisting of a high-refractive-index transparent adhesive, a white high-reflectivity resin, a microlens array, and a patterned black matrix (BM).

Researchers have improved the light emission angle from the top of the chip by introducing a gradient refractive index layer on the Micro LED chip, raising the critical angle from 25 degrees to a maximum of 65.9 degrees, which significantly improves the top light extraction efficiency.

Meanwhile, the white reflective resin forms an isosceles trapezoidal structure between the chips, which can concentrate and scatter light, increasing the brightness by about 27% at a 0° viewing angle, and ensuring smooth light output through plasma removal of residual colloids.

In the light control section, the team used nanoimprint technology to fabricate a high-precision lens array, achieving effective convergence of light within ±60°.

Simulation results show that when the lens curvature is 0.03 and the refractive index is 1.85, the light intensity is increased by more than 53%. In addition, the study also effectively reduced the reflectivity to less than 2% and achieved a high contrast ratio of more than 20,000:1 by introducing a patterned black matrix into the encapsulation glass layer, significantly improving the display quality.

(a) MicroLED structure, (b) Light emission direction inside the chip, (c) Light distribution (Image source: Information Display)

BOE's research team stated that this solution not only achieves breakthroughs in optical efficiency and uniformity but also ensures packaging reliability. The combination of the glass cover and the OCA layer enhances waterproofing, oxidation resistance, and abrasion resistance, providing a reliable path for the mass production application of Micro LED in fields such as automotive displays, AR/VR headsets, and wearable devices.

BOE has not only achieved the latest Micro LED research results, but is also continuously promoting the development of Mini/Micro LED direct-view display technology and applications.

On October 30th, BOE Technology Group and TrendForce Display will jointly host the 2025 Self-Emitting Display Industry Seminar in Shenzhen. At the seminar, Gao Bo, Minister of Chip Technology at BOE, will deliver a speech entitled "Overview of Direct-Show COG Technology Trends," sharing BOE's latest developments in Mini/Micro LED direct-show technology. All are welcome to attend.