With the deep empowerment of AI technology, the rapid improvement of hardware performance, the active exploration of innovative enterprises, and the strong entry of major technology companies, the AR glasses market continued to heat up in 2025, driving the AR glasses industry into a new development period.

Driven by the AR glasses boom, the application of Micro-LED micro-display technology, characterized by high brightness, high resolution, and low power consumption, in end-products is gradually increasing. According to incomplete statistics, as of now, 15 new AR glasses products equipped with Micro-LED micro-display technology have been released by 2025.

Despite the continued growth in end-user applications, from the perspective of the display industry chain, the development of Micro-LED micro-display technology toward large-scale application still faces many obstacles.

At the 2025 Self-Emitting Display Symposium, Guo Xiao, an expert in GaN epitaxial process on silicon substrates at LONGi Optoelectronics, pointed out that Micro-LED micro-display technology is still facing challenges in terms of chips, full-color display, driving, testing, and cost. LONGi Optoelectronics is working to optimize these issues from the upstream epitaxial process.

Guo Xiao, expert in GaN epitaxial processes on silicon substrates for crystal energy optoelectronics

The implementation of Micro-LED micro-display technology faces difficulties, and traditional substrate technology encounters bottlenecks. The "2025 Near-Eye Display Market Trends and Technology Analysis" previously predicted that by 2030, the shipment of AR devices equipped with Micro-LED micro-display technology will reach 20 million units, with a penetration rate of 65.0%.

The industry is optimistic about the prospects of Micro-LED micro-display technology, and thanks to the industry's long-term efforts, the technology has made great progress. However, the problem of industrialization still exists.

Guo Xiao believes that the challenges of Micro-LED micro-display technology are distributed across the entire industry chain. In terms of driving, the voltage difference of RGB three-color chips is large and the brightness consistency is difficult to control. At the same time, the size matching of CMOS and epitaxy is difficult and the power consumption is relatively high. In terms of detection, AOI and PL detection and screening are difficult. In terms of chips, epitaxial wavelength consistency and particle control are both difficult problems. In terms of full color, whether it is three-color light combining, quantum dot color conversion or vertical stacking, there are their own difficulties and the technology is not yet mature.

Among all the challenges, cost and integration are among the core difficulties of Micro-LED microdisplay technology, which directly point to the bonding process and substrate material selection of Micro-LED microdisplays.

Currently, the bonding methods for Micro-LED microdisplays mainly include Die to Die, Die to Wafer, and Wafer to Wafer (W2W).

Guo Xiao believes that, overall, W2W bonding technology is more suitable for Micro-LED micro-display applications. This process first thermally bonds the silicon-based CMOS wafer and the LED epitaxial wafer, and then removes the substrate by wet or laser lift-off.

The advantage of W2W bonding is that it does not require high alignment accuracy. However, on the other hand, this technology also has extremely strict requirements on epitaxial yield and uniformity, as well as warpage control during the bonding process. These pose new challenges to epitaxial wafers with traditional sapphire substrates.

The first issue is the size mismatch problem in the crucial wafer-to-wafer (W2W) bonding process. Currently, silicon-based CMOS wafers driving Micro-LEDs can be made from 8 to 12 inches, but the mainstream size of sapphire substrate epitaxial wafers supporting the LEDs is only 6 inches. This mismatch makes sapphire substrate epitaxial wafers incompatible with the most advanced silicon CMOS processes.

Secondly, size limitations also restrict the path to cost reduction for Micro-LEDs. Developing larger wafer sizes (such as 12 inches) to reduce the cost per chip is an important path to cost reduction for Micro-LEDs, but the physical limitations of 6-inch sapphire substrates prevent it from enjoying this benefit.

Finally, the combination of sapphire and silicon, two different materials, also presents significant technological challenges. During hot-press bonding, the difference in their coefficients of thermal expansion (thermal mismatch) can easily lead to wafer warping, which greatly increases the difficulty of the process and directly threatens the yield and color uniformity of the final product.

Therefore, the process bottlenecks arising from the application of sapphire substrates and silicon-based CMOS have become one of the biggest obstacles to achieving high-yield and low-cost manufacturing of Micro-LED microdisplay technology. The industry urgently needs a substrate technology that can perfectly match silicon-based CMOS, and silicon substrate technology has gradually come to the forefront in this context, with Lattice Optoelectronics becoming a major developer of this technology.

Crystal Optoelectronics' GaN technology on silicon substrates facilitates the application of Micro-LED microdisplay technology . Compared to sapphire substrate technology, silicon substrates are more suitable for the manufacturing and application of Micro-LED microdisplay technology.

Silicon substrates offer advantages such as easy large-size manufacturing, low substrate cost, high wavelength consistency, small warpage of homogeneous bonding, non-destructive removal, and CMOS compatibility. They can fully leverage integrated circuit processes and equipment to achieve high-yield, low-cost, and high-efficiency manufacturing of Micro-LED microdisplay modules.

Based on these characteristics, silicon substrate epitaxy technology is also considered by the industry to be a key driver for the future industrialization of Micro-LED microdisplays.

However, silicon substrate epitaxy technology is still in its development stage, and Crystal Power Optoelectronics has become one of the few companies in the industry that continues to promote the development of silicon substrate epitaxy technology.

In response to the bottlenecks hindering the practical application of Micro-LEDs, LONGi Optoelectronics has provided a solution based on GaN technology on silicon substrates.

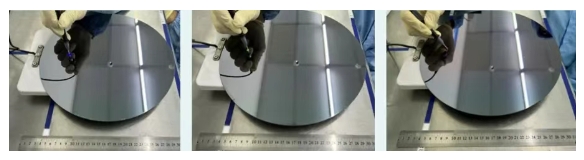

Addressing the challenge of size mismatch, LONGi Optoelectronics has taken the lead in implementing 12-inch large-size silicon substrate GaN-based red, green, and blue three-primary-color Micro-LED epitaxial technology.

By optimizing growth using a stress accumulation and release model for heteroepitaxial growth and innovatively utilizing lattice stress-induced dislocation reactions, Lattice Power Optoelectronics has achieved stable and repetitive growth of GaN epitaxial layers on silicon substrates with a dislocation density of 1.5E8/cm2 under a total epitaxial layer thickness of 5μm, thus solving the crystal quality problem of large-size silicon substrate epitaxial materials.

Rapid test EL lighting effect of red, green, and blue InGaN-based LED epitaxial wafers on a 12-inch silicon substrate by Lattice Optoelectronics (Image source: Lattice Optoelectronics)

To address the challenge of full-color Micro-LEDs, Lattice Power has also developed 8-inch silicon substrate LED epitaxial wafers with a full color range of 365nm to 650nm. Among them, the EQE of the mass-produced silicon substrate vertical structure blue, green, and ultraviolet mid-power LED chips is basically the same as that of the mass-produced sapphire substrate vertical structure.

Regarding the challenge of red light efficiency in the Micro-LED industry, LONGi Optoelectronics has mastered internationally leading silicon substrate InGaN red light epitaxy technology and will continue to improve InGaN red light efficiency in the future.

In the application of Micro-LED matrix automotive lighting, LONGi Optoelectronics has developed a 10,000-pixel automotive lighting product based on GaN on a silicon substrate.

Micro-LED automotive lights with tens of thousands of pixels based on GaN on silicon substrates (Image source: Lattice Power Optoelectronics)

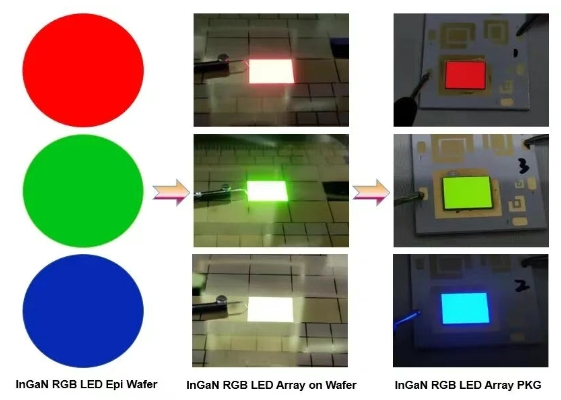

In addition, LONGi Optoelectronics is also actively developing high PPI Micro-LED array technology based on silicon substrates, and has taken the lead in preparing a full InGaN series of three-color Micro-LED micro-display matrix, comprehensively promoting the development of Micro-LED micro-display technology.

Full InGaN series tri-color Micro-LED micro-display matrix (Image source: Lattice Power Optoelectronics)

Today, LONGi Optoelectronics' large-size silicon substrate GaN material has been applied by well-known micro-display companies such as NONGi Technology and HONGShi Intelligent, developing ultra-high brightness and monolithic full-color Micro-LED micro-display chips, and is promoting the mass production of products, continuing to accelerate the industrialization of Micro-LED micro-displays.

Summary <br /> In the field of silicon substrate GaN materials, LONGi Optoelectronics has been deeply involved for nearly 20 years. Its industrial chain has covered epitaxial chips and device modules, forming a closed-loop feedback and iterative upgrade capability of GaN LED technology in the epitaxial chip device market.

Today, LONGi Optoelectronics is actively participating in empowering the development of the AR glasses industry, using silicon substrate GaN technology to help the mature application of Micro-LED microdisplays, a key component of AR glasses.

In the future, as leading companies across the entire industry chain, such as LONGi Optoelectronics, drive the continued evolution of silicon substrate GaN Micro-LED technology towards 8-inch and 12-inch sizes, the cost reduction and yield ramp-up speed of Micro-LED microdisplays will exceed industry expectations. (Text: Irving)